Flanges

Alloy Alliance has emerged as a trusted global supplier and exporter of high-quality industrial flanges, serving diverse industries with an extensive range of precision-engineered flange solutions. Our comprehensive product portfolio includes slip-on flanges, weld neck flanges, blind flanges, socket weld flanges, threaded flanges, lap joint flanges, and orifice flanges, each designed to meet specific piping system requirements across various industrial applications. We cater to critical sectors including oil and gas, petrochemicals, power generation, chemical processing, pharmaceuticals, water treatment, and marine engineering, where reliable flange connections are essential for system integrity and safety.

Our flanges are manufactured from premium materials including carbon steel, stainless steel grades 304, 316, 321, and 347, alloy steel, duplex and super duplex steel, as well as exotic materials such as Inconel, Hastelloy, Monel, and titanium alloys. We offer flanges in compliance with international standards including ANSI B16.5, ANSI B16.47, ASME B16.36, DIN, EN, JIS, and BS specifications, covering pressure classes from 150 to 2500 and sizes ranging from half-inch to large diameter applications. Each flange type is engineered to provide optimal performance under specific pressure, temperature, and corrosive conditions.

Quality assurance forms the cornerstone of our operations, with every flange undergoing rigorous testing including dimensional verification, hardness testing, impact testing, and hydrostatic pressure testing to ensure compliance with stringent international standards. Our products come with complete material traceability documentation, mill test certificates, and third-party inspection reports when required, providing customers with complete confidence in product reliability and performance.

As experienced exporters, Alloy Alliance provides comprehensive support services including technical consultation, custom manufacturing capabilities, surface treatments such as galvanizing and coating, and efficient global logistics management. Our technical team works closely with clients to recommend appropriate flange types, materials, and specifications based on their specific application requirements, ensuring optimal system performance, safety, and cost-effectiveness across diverse industrial projects worldwide.

Specifications

| Specification | ASTM A182 / ASME SA182 |

| Supporting Flange Material | Flanges Bolts, Ring Joint, Gasket |

| Design For Size | JIS Flanges, ANSI Flanges, BS Flanges, EN Flanges, ASA Flanges, ASME Flanges, DIN Flanges, PN Flanges |

| Common Types of SS Flange | Flanges 150 LB WNRF 600# BLRF Class 300 RTJ Class 900 SORF |

| Size Chart | 1/2″ (15 NB) To 48″ (1200NB) |

| Production Process | Forged, Heat Treated and Machined |

| Stainless Steel 304 Flanges Coating Flange Faces | Zinc Plated, Yellow Transparent, Oil Black Paint, Anti-rust Paint, Cold and Hot Dip Galvanized |

| Application | Chemical Industry Water Pipeline Industry Nuclear Power Plant Fabrication Industry Natural Gas Industry Oil And Gas Industry |

| Standards | JIS Flanges, ISO Flanges, GOST Flanges, UNI Flanges, AWWA Flanges, MSS SP44 Flanges, ASME B16.5 Flanges, ASME B16.38 Flanges, EN-1092 Flanges, BS10 Flanges, DIN Flanges, PN Flanges, ASME B16.47 (Series A, Series B) Flanges |

| Pressure Rating Table | Class 150 LBS, Class 300 LBS, Class 600 LBS, Class 900 LBS, Class 1500 LBS, Class 2500 LBS |

| Connect Type Type | RF, FF, RTJ, LMF, SMF, LJF |

| Flange Machining Equipment | Sand-blasting machine, Press machine, Bending machine, Pushing Machine, electric bevelling machine etc |

Different Types Of Flanges

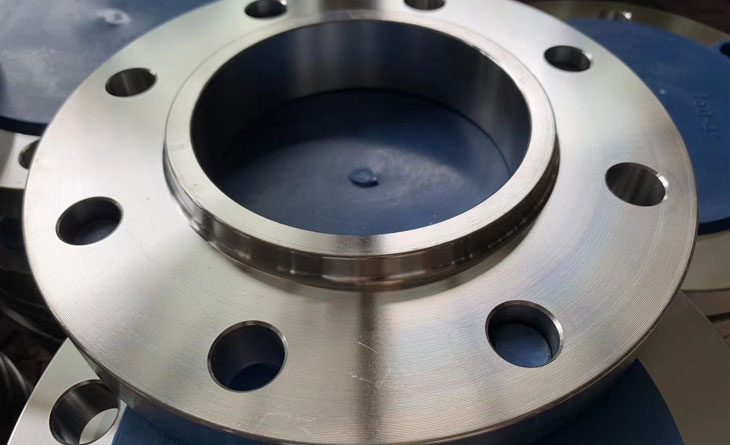

Welding Neck Flanges

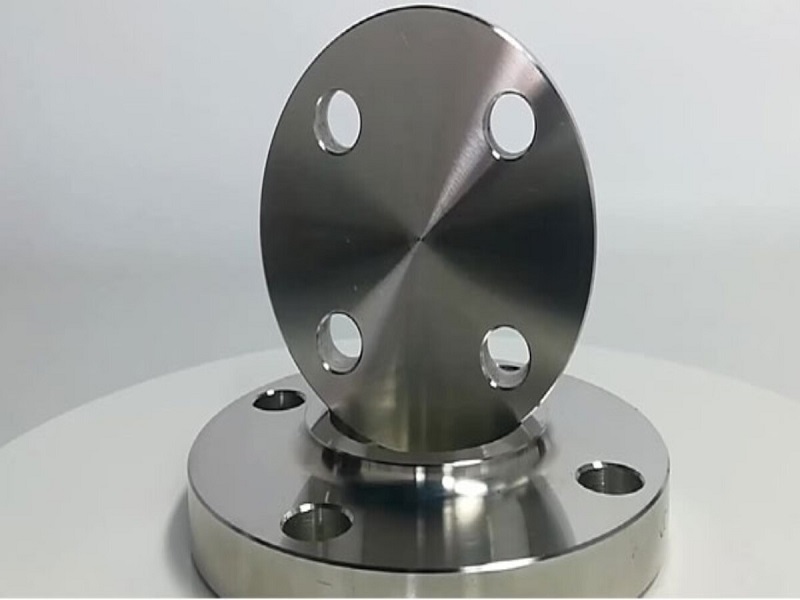

Blind Flanges

Slip on Flanges

Socket Weld Flanges

Lap Joint Flanges

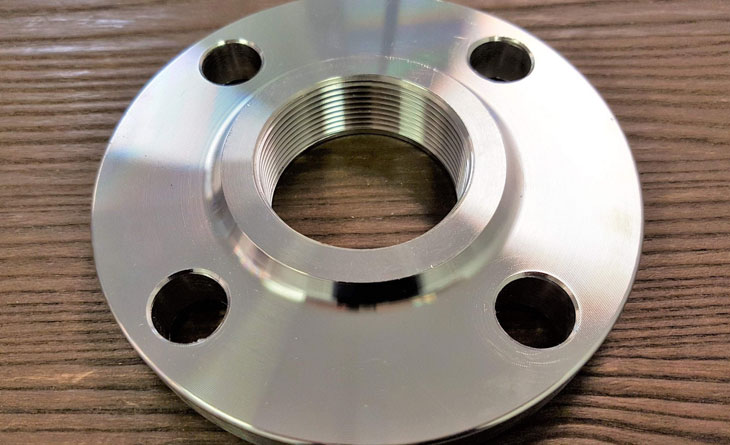

Threaded Flanges

Material & Grade

| Stainless Steel | ASTM A182 , A240 F 202, 304, 304L, 304H, 316, 316Ti, 316H, 316L, 316LN, 309S, 309H, 310S, 310H,317, 317L, 321, 321H, 347, 347H, 201, 202, 904L |

| Duplex Steel | ASTM A182, A240 UNS F 44, F 45, F51, F 53, F 55, F 60, F 61 |

| Super Duplex Steel | ASTM A182 / ASME SA182 UNS NO. S32750 / S32760 / S32950 |

| Carbon Steel | ASTM / ASME A 105, A53 GR B, A106GR B, API5L GRADE B, API 5L, GRX42 / 46 / 52 / 56 / 60 / 65 / 70, A333 GR 1/GR 3/GR 6, A/SA 672 GR 8C60/C70 etc.. |

| Alloy Steel | ASTM / ASME A182 GR F 5, F 9, F 11, F 12, F 22, F 91. |

| Nickel Alloy | ASTM SB564, SB160, SB472, SB162 Nickel 200 (N02200), Nickel 201 (N02201), Nickel 205 (N02205) |

| Monel | ASTM / ASME SB164 Monel 400 (N04400), Monel 500 (N05500) |

| Inconel | ASTM SB564, SB160, SB472, SB162 Inconel 600, Inconel 601, Inconel 625, Inconel 625LCF, Inconel 686, Inconel 718, Inconel 800, Inconel 825, Inconel X-750, Incoloy 800, incoloy 825, Incoloy 925, Incoloy a-286 |

| Hastelloy | ASTM SB564, SB160, SB472, SB162 Hastelloy C22, Hastelloy C276, Hastelloy C4, Hastelloy B, Hastelloy C-2000 |

| Cupro Nickel Alloy | ASTM SB61, SB62, SB151, SB152 UNS No. C70600 (Cu-Ni 90/10), C71500 (Cu-Ni 70/30), UNS No. C10100, 10200, 10300, 10800, 12000, 12200 |

Equivalents of grade Flanges

|

MATERIAL

|

ASTM | EQUIVALENT STANDARD | |||

| UNS | GRADE (TP) | DIN (EN) | AFNOR (NF) | JAPAN (JIS) | |

|

AUSTENTIC STAINLESS STEEL

|

S30400 | 304 | 1.4301 | Z6CN18-09 | SUS304 |

| S30403 | 304L | 1.4307 | Z2CN18-10 | SUS304L | |

| S31600 | 316 | 1.4401 | Z6CND17-11 | SUS316 | |

| S31603 | 316L | 1.4404 | Z2CND17-12 | SUS316L | |

| S31635 | 316Ti | 1.4571 | Z2CND17-12 | - | |

| S32100 | 321 | 1.4541 | Z6CNT18-10 | SUS321 | |

| S34700 | 347 | 1.455 | Z6CNNb18-10 | SUS347 | |

| S30409 | 304H | 1.4948 | Z6CN19-10 | SUS304H | |

| S31609 | 316H | 1.4919 | Z6CND17-12 | SUS316H | |

| S32109 | 321H | 1.4941 | Z10CND18-10 | SUS321H | |

| S31000 | 310 | - | - | SUS310 | |

| S31703 | 317L | 1.4438 | - | SUS317L | |

|

FERRITIC STAINLESS STEEL

|

S40500 | 405 | 1.4002 | Z6CAL13 | SUS405 |

| S41000 | 410 | 1.4006 | Z12C13 | SUS410 | |

| S43000 | 430 | 1.4016 | Z10C17 | SUS430 | |

|

DUPLEX STAINLESS STEEL

|

S32205 | 2205 | 1.4462 | Z2CND22-06 | - |

| S31803 | - | 1.4462 | Z2CND22-05 | - | |

Application Industries

Alloy Alliance supplies high-quality steel products to a range of industries, including petrochemical, chemical, pharmaceutical, oil and gas, nuclear, and offshore sectors. Our products are engineered to meet stringent industry standards, ensuring durability and reliability. With a robust stock and tailored solutions, Rajsheel Steel Industries supports critical infrastructure worldwide.

Petrochemical

Chemical

Pharmaceutical

Oil & Gas

Nuclear

Offshore

Packing Of Flanges

Alloy Alliance carefully packages its products to ensure secure delivery and protection. Depending on client needs, items are packed in shrink-wrap, carton boxes, wooden pallets, wooden boxes, and wooden crates. Each packaging method is chosen for durability and safety, ensuring Alloy Alliance steel products arrive in excellent condition for various industries.